Exhibition place:Fashion Gallery

Exhibition time:2018.5 - 2018.9

According to Joseph Needham, the character“机” (ji) in ancient Chinese has double meanings: (1) Loom; (2) Matter of wit and intelligence. These definitions equate loom with the ability to learn and invent. People from all corners of the world share the knowledge of loom and weaving. However, as this exhibit attests, different regions in different periods develop specific looms to produce unique textile types.

A World of Looms is organized by the China National Silk Museum with the support of many scholars and research institutions. It is the first exhibition in China to present the rich cultural heritage of looms and weaving technologies from around the world. The displays include more than 50 looms and many of their associated textiles, organized by their geographical locations. These objects celebrate the marches of textile innovations through the lens of global textile traditions: It highlights the vital role of cultural exchanges along the Silk Road for the evolution of loom types in China and its bordering regions. Furthermore, it illustrates the adaptions of looms and weaving practice worldwide in facing the rapid change of traditional custom and in meeting new demands. Last, it emphasizes the need to preserve weaving knowledge, for it is quintessential to all cultures. (Zhao Feng)

1. CHINA

China has a long and rich history related to weaving and loom. Preliminary loom has been developed more than 7000 years ago. The Warring States and Han Dynasty (5th century BCE – 2nd century CE) saw the evolution of treadle and multi-heddle looms. This is also the time when weaving technology reached its historical peak. Through the cultural exchanges on the Silk Roads, drawloom was developed; it achieved its final form before the Tang Dynasty (7th–9th century) and became the dominant system for weaving patterned silks from the Song Dynasty to the Qing Dynasty (10th–19th century). On the UNESCO list, the cultural heritages preserved from the China past include both the tangible and the intangible. Among these are the excavated pattern loom models from the Han Dynasty as well as the Sericulture and Silk Craftsmanship of China, which include the weaving and loom of both the Han and the Minority Groups. (Zhao Feng)

1.1 Early Looms

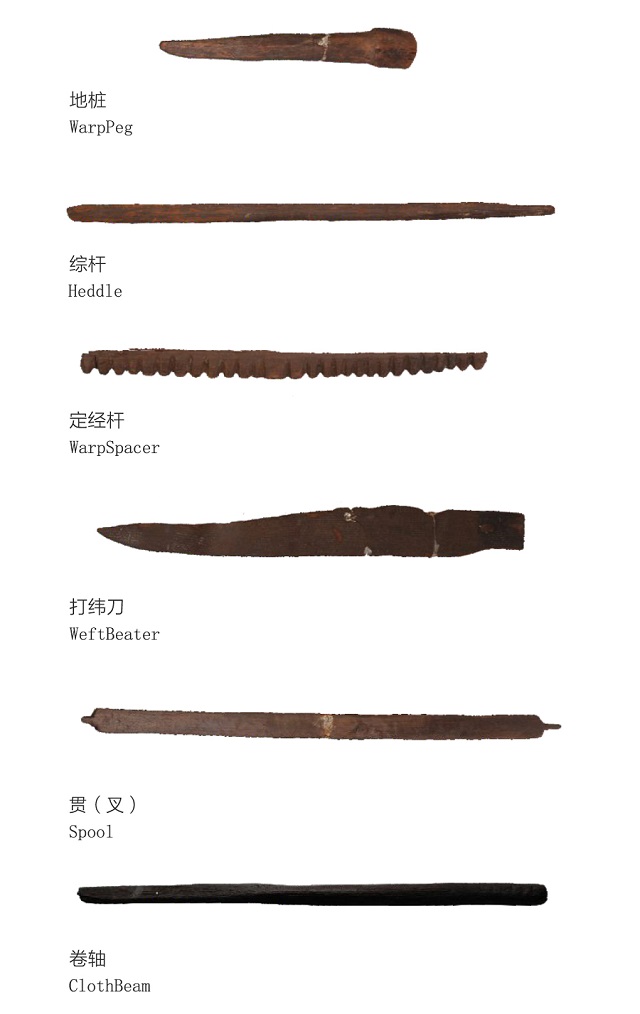

Early looms in China are mostly simple backstrap looms, where the warp is stretched between some stationary objects and the body of the weaver. The foundation weave is generally plain weave. The two plain weave sheds are called natural shed and counter shed. The first is operated by means of a shed roll over which one set of warp pass, and the second by a continuous string heddle which encase individual thread of the other set of warp. Weavers lean back and forth, using their body weight to adjust tension of the warp. As they lean forward, the tension is relaxed and they can raise the string heddle to open one shed. As they lean back, the warp is stretched and turns to its natural shed with the shed roller. The weavers can then draw the shed roll towards them to widen the shed. (Long Bo)

Tianluoshan Loom Dated to 6,500 years ago, wooden

Excavated from Yuyao, Zhejiang Province

Collection of Zhejiang Institute of Archaeology

The Tianluoshan site is located in Yuyao City, and belongs to the ancient Hemudu culture. The loom parts excavated from the Tianluoshan site come from simple backstrap looms. In such loom, one end of the warp would be tied to a warp beam. In the middle, there would be a heddle rod and a weft beater. The other end of the warp is connected to a cloth beam, which is strapped to the waist of the weaver. (Long Bo)

Liangzhu Jade Loom Jade

Unearthed from Liangzhu, Zhejiang Province

Collection of Liangzhu Museum

Loom parts made of jade were excavated at the Liangzhu Cultural Cemetery in Yuhang District, Hangzhou in 1986. Three pairs of six end-pieces of loom parts were found in symmetrical alignments, each pair were placed 35 cm apart. The gaps must indicate the now-missing wooden rods that have deteriorated over time. These end-pieces are enough evidence to visually construct a simple backstrap loom. (Long Bo)

Shizhaishan Bronze Loom

Bronze Excavated from Jinning, Yunnan Province

Collection of Yunnan Museum

Four loom parts made of bronze were excavated from the Shizhaishan site, Jinning, Yunnan Province. They consist of a warp beam, a heddle rod, a weft beater, and a cloth beam. Together they form a simple backstrap loom. This site and the Lijiashan site in Jiangchuan have also yielded two bronze cowrie containers that depict a scene of a textile workshop. Both sites are dated to the Western Han Dynasty (206 BCE–8 CE). (Long Bo)

Laoguanshan Pattern Loom

Four models of hook-shaft pattern loom were excavated in 2012 inside the Laoguanshan Han Dynasty tomb in Chengdu, Sichuan Province. They were constructed of wood and bamboo and discovered at the bottom of a wooden coffin, along with remnants of silk threads and dyes. The largest of the four looms measures H. 50 x L.70 x W. 20 cm. The other three are smaller, around H.45 x L.60 x W.15 cm. Of equal interest, there were 15 painted wooden figurines, which—as indicated by their postures and accompanying inscriptions—may be representations of workers at a weaving workshop where Sichuan jin silks were produced. To date, these miniature looms are the only complete loom models from the Han dynasty that bear a confirmed provenance. (Long Bo)

1.2. Treadle Looms

Treadle loom is a generic term for a loom equipped with a pedal that is used to lift a shed opening device. The use of pedal changed the simple shedding system operated by hand to the treadle-lifting shedding system operated by feet. The new system free up the hands from picking up and beating the wefts and greatly improved the efficiency of weaving. Treadle loom first appeared in China during the Spring and Autumn and the Warring States Dynasties. The first visual depiction of the loom, however, is found in the Eastern Han Dynasty. There are several types of pedal loom with different number combination of heddles and treadles. (Long Bo)

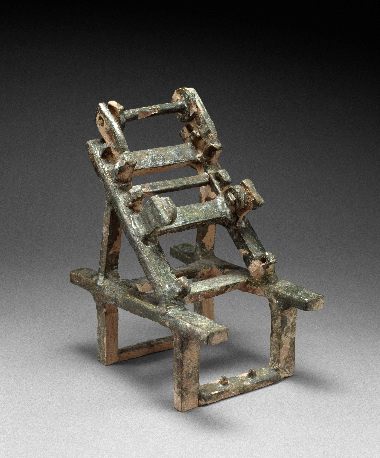

Ceramic Loom Model (3D Print)

H.30 cm x L.25 cm x W.17 cm Han Dynasty (202 BCE–220 CE)

The original is in the collection of the Musée Guimet

A loom model of green-glazed ceramic, dated to the Han Dynasty, was collected by Mrs. Riboud, a well-known Chinese textile history expert. Although it has no exact excavation provenance, this object is a very important material in the study of Han Dynasty looms. The form of the loom conforms to the oblique treadle looms depicted on numerous stone relief carvings from the Han Dynasty. (Long Bo)

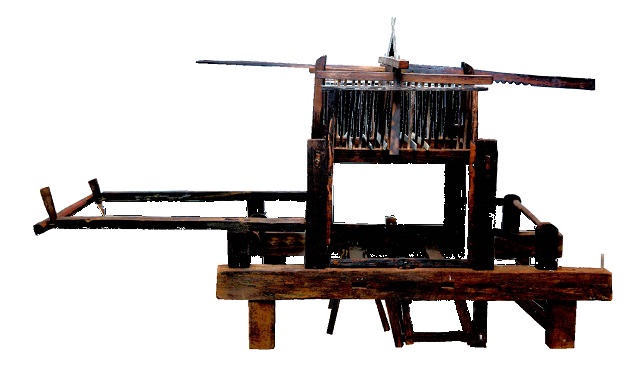

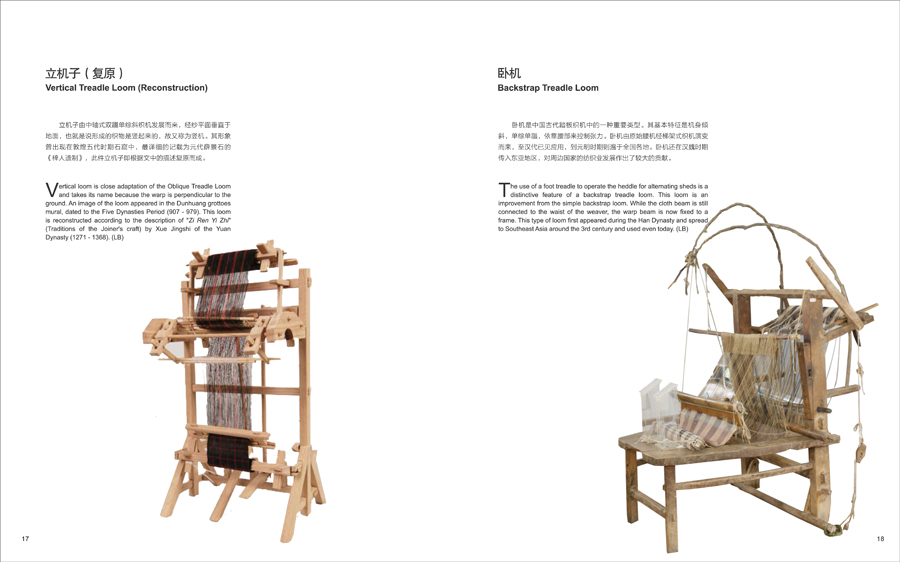

Vertical Treadle Loom (Reconstruction)

Vertical loom is close adaptation of the Oblique Treadle Loom and takes its name because the warp is perpendicular to the ground. An image of the loom appeared in the Dunhuang grottoes mural, dated to the Five Dynasties Period. This loom is reconstructed according to the description of "Zi Ren Yi Zhi" (Traditions of the Joiner’s craft) by Xue Jing Shi of the Yuan Dynasty. (Long Bo)

Backstrap Treadle Loom

The use of a foot treadle to operate the heddle for alternating sheds is a distinctive feature of a backstrap treadle loom. This loom an improvement from the simple backstrap loom. While the cloth beam is still connected to the waist of the weaver, the warp beam is now fixed to a frame. This type of loom first appeared during the Han Dynasty and spread to Southeast Asia around the 3rd century. (Long Bo)

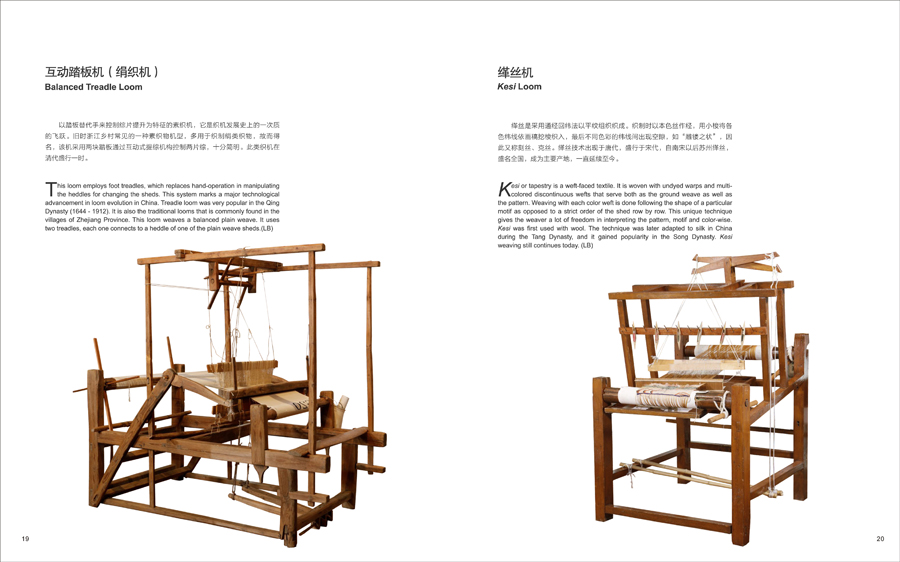

Balanced Treadle Loom

This loom employs foot treadles, which replaces hand-operation in manipulating the heddles for changing the sheds. This system marks a major technological advancement in loom evolution in China. Treadle loom was very popular in the Qing Dynasty. It is also the traditional looms that is commonly found in the villages of Zhejiang Province. This loom weaves a balanced plain weave. It uses two treadles, each one connects to a heddle of one of the plain weave sheds. (Long Bo)

Kesi Loom

Kesi or tapestry is a weft-faced textile. It is woven with undyed warps and multi-colored discontinuous wefts that serve both as the ground weave as well as the pattern. Weaving with each color weft is done following the shape of a particular motif as opposed to a strict order of the shed row by row. This unique technique gives the weaver a lot of freedom in interpreting the pattern, motif and color-wise. Kesi was first used with wool. The technique was later adapted to silk in China during the Tang Dynasty, and it gained popularity in the Song Dynasty. Kesi weaving still continues today. (Long Bo)

1.3 Pattern Looms

Large and complicated patterns require a more sophisticated patterning system that allows repetition of some actions at regular intervals. In other words, the loom needs a system that allows both the storage and easy retrieval of the pattern. This need was answered by the heddles and shafts system, which led to the development of multi-shafts patterning looms and the drawloom. (Long Bo)

Taiwan Atayal Loom

This is a unique type of backstrap loom used by some aboriginal groups in Taiwan. The cloth beam is secured at the weaver’s waist, while the large, hollow warp beam (on the right in the photograph) rests behind the weaver’s feet. To adjust the tension in the warp the weaver flexes the warp beam with her feet. Fibers for weaving include hemp, ramie, cotton and hibiscus. Stripe patterns and small geometric designs are made using various aids, including heddles and sticks embedded in the warp. Weaving on this type of loom had become rare, but recently there has been a revival of interest in traditional weaving in Taiwan. (Long Bo)

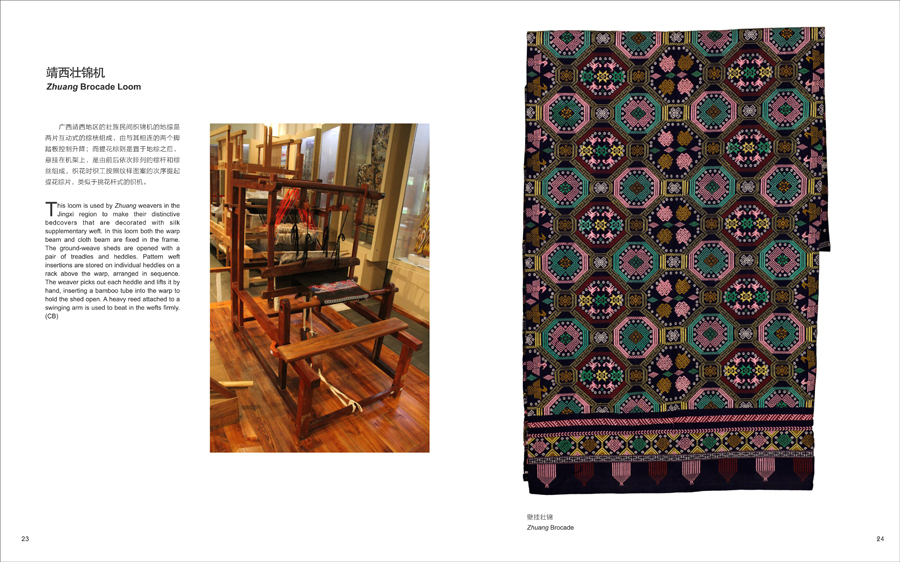

Zhuang Brocade Loom

This loom is used by Zhuang weavers in the Jingxi region to make their distinctive bedcovers that are decorated with silk supplementary weft. In this loom both the warp beam and cloth beam are fixed in the frame. The ground-weave sheds are opened with a pair of treadles and heddles. Pattern weft insertions are stored on individual heddles on a rack above the warp, arranged in sequence. The weaver picks out each heddle and lifts it by hand, inserting a bamboo tube into the warp to hold the shed open. A heavy reed attached to a swinging arm is used to beat in the wefts firmly. (Long Bo)

Wang Hanging of Zhuang Brocade

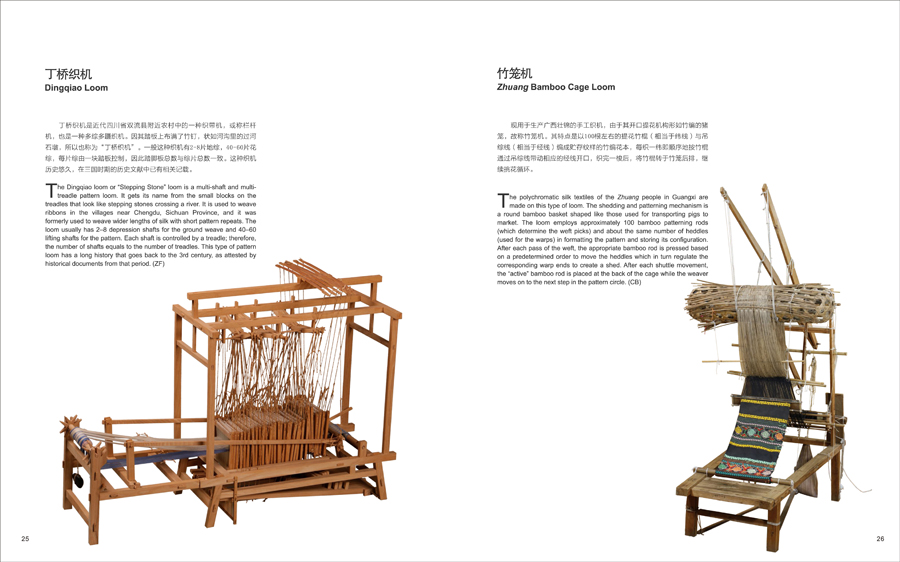

Dingqiao Loom

The Dingqiao loom or “Stepping Stone” loom is a multi-shaft and multi-treadle pattern loom. It gets its name from the small blocks on the treadles that look like stepping stones crossing a river. It is used to weave ribbons in the villages near Chengdu, Sichuan Province, and it was formerly used to weave wider lengths of silk with short pattern repeats. The loom usually has 2–8 depression shafts for the ground weave and 40–60 lifting shafts for the pattern. Each shaft is controlled by a treadle; therefore, the number of shafts equals to the number of treadles. This type of pattern loom has a long history that goes back to the 3rd century, as attested by historical documents from that period. (Long Bo)

Zhuang Bamboo Cage Loom

The polychromatic silk textiles of the Zhuang people in Guangxi are made on this type of loom. The shedding and patterning mechanism is a round bamboo basket shaped like those used for transporting pigs to market. The loom employs approximately 100 bamboo patterning rods (which determine the weft picks) and about the same number of heddles (used for the warps) in formatting the pattern and storing its configuration. After each pass of the weft, the appropriate bamboo rod is pressed based on a predetermined order to move the heddles which in turn regulate the corresponding warp ends to create a shed. After each shuttle movement, the “active” bamboo rod is placed at the back of the cage while the weaver moves on to the next step in the pattern circle. (Long Bo)

Dai Brocade Loom

This distinctive loom is used by Dai weavers in the Jinghong region of Yunnan Province. The cloth beam is attached to the weaver’s waist, and the warp beam is lodged in the loom frame. There are two treadles: depressing one raises the heddle that opens the ground weave shed, while depressing the other raises the pattern harness. Patterns are stored on loop threads or sticks in a pattern harness that stretches above and below the loom: each loop records one pattern weft insertion. After each pass of the weft, the ‘active’ loop, is transferred from the top of the pattern harness to the underneath part. A loom may have as many as 100 looped threads. Similar patterning systems are used by Tai weavers in Vietnam, Laos and Thailand, though the looms used by these weavers are fundamentally different. (Long Bo)

Dai Brocade with Peacock and Elephant Pattern

Dong (Kam) Brocade Loom

Commonly known as “Douji,” this loom is unique to the Dong people living in the Tongdao area of Hunan and parts of nearby Guizhou Province. They use it to weave cloth decorated with supplementary weft, for use on baby carriers and wedding bedcovers. The warp beam is fixed in the loom, and the cloth beam is attached to the weaver’s waist. The weaver has two loops of cord around her feet: pulling one raises the ground-weave heddle, while pulling the other raises the pattern heddle. Pattern weft insertions are stored on sticks above the warp, in a system that is similar to the brocade loom used by Dai weavers in Yunnan Province. The ground-weave is usually cotton, while the colorful wefts can be either cotton or silk. (Long Bo)

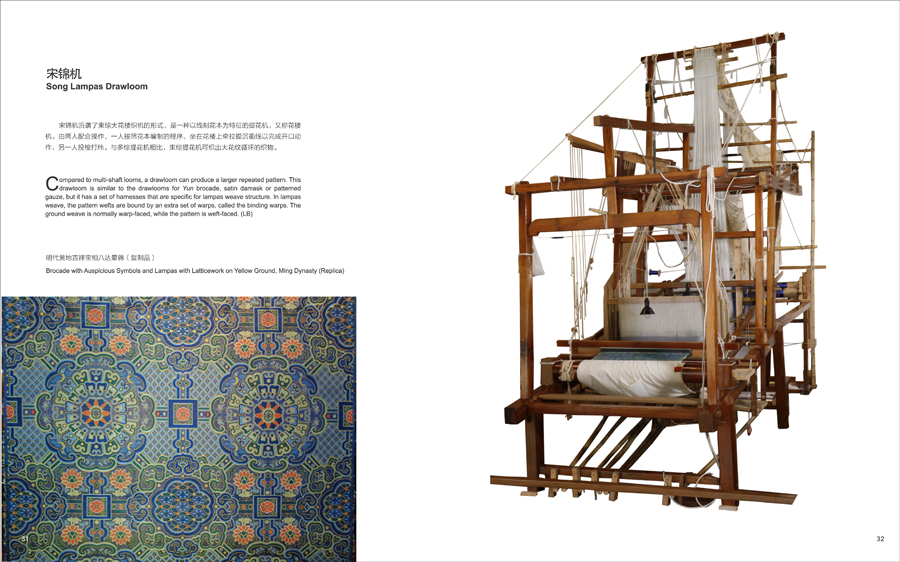

Song Lampas Drawloom

Compared to multi-shaft looms, a drawloom can produce a larger repeated pattern. This drawloom is similar to the drawlooms for Yun brocade, satin damask or patterned gauze, but it has a set of harnesses that are specific for lampas weave structure. In lampas weave, the pattern wefts are bound by an extra set of warps, called the binding warps. The ground weave is normally warp-faced, while the pattern is weft-faced. (Long Bo)

Brocade with Auspicious Symbols and Lampas with Latticework on Yellow Ground, Ming Dynasty (Replica)

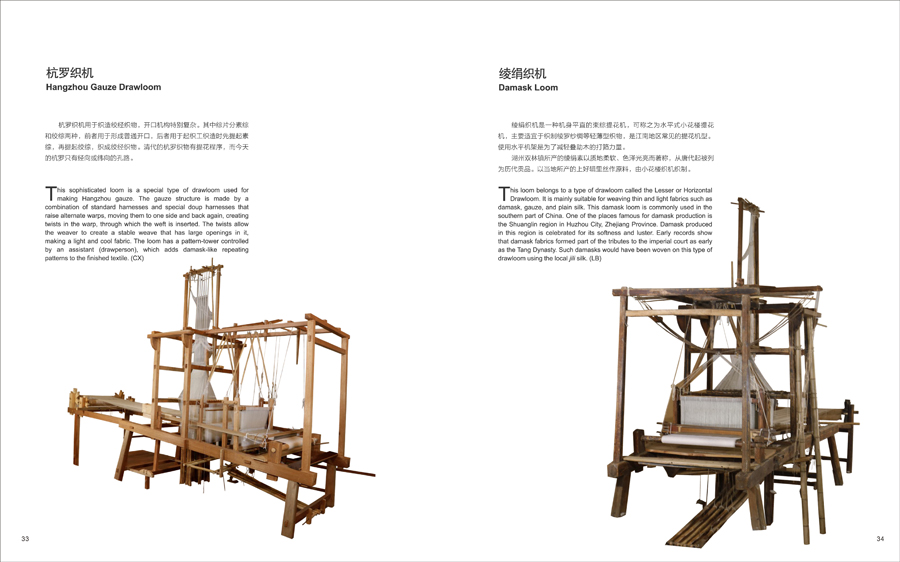

Gauze Loom

This sophisticated loom is a special type of drawloom used for making Hangzhou gauze. The gauze structure is made by a combination of standard harnesses and special doup harnesses that raise alternate warps, moving them to one side and back again, creating twists in the warp, through which the weft is inserted. The twists allow the weaver to create a stable weave that has large openings in it, making a light and cool fabric. The loom has a pattern-tower controlled by an assistant (drawperson), which adds damask-like repeating patterns to the finished textile. (Long Bo)

Damask Loom

This loom belongs to a type of drawloom called the Lesser or Horizontal Drawloom. It is mainly suitable for weaving thin and light fabrics such as damask, gauze, and plain silk. This damask loom is commonly used in the southern part of China. One of the places famous for damask production is the Shuanglin region in Huzhou City, Zhejiang Province. Damask produced in this region is celebrated for its softness and luster. Early records show that damask fabrics formed part of the tributes to the imperial court as early as the Tang Dynasty. Such damasks would have been woven on this type of drawloom using the local jili silk. (Long Bo)

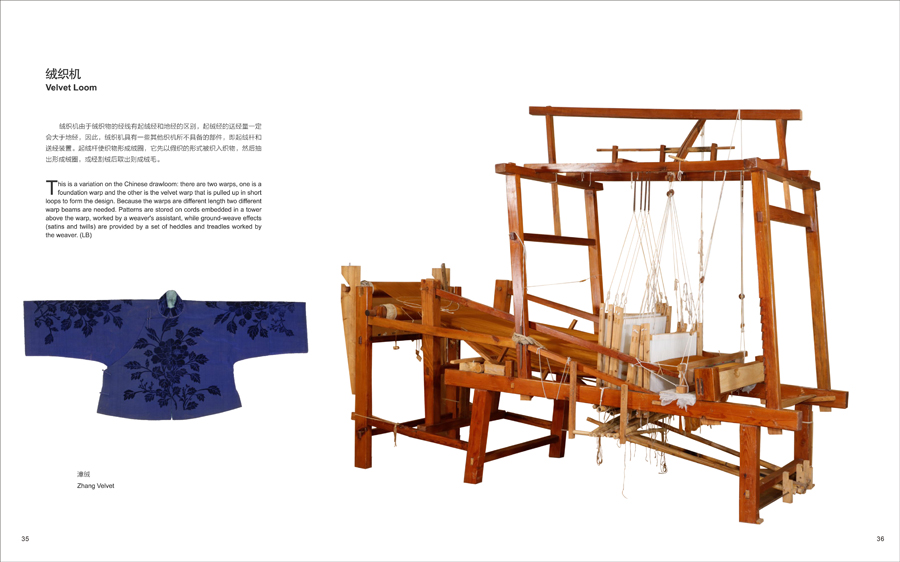

Velvet Loom

This is a variation on the Chinese drawloom: there are two warps, one is a foundation warp and the other is the velvet warp that is pulled up in short loops to form the design. Because the warps are different length two different warp beams are needed. Patterns are stored on cords embedded in a tower above the warp, worked by a weaver’s assistant, while ground-weave effects (satins and twills) are provided by a set of heddles and treadles worked by the weaver. (Long Bo)

Zhang Velvet

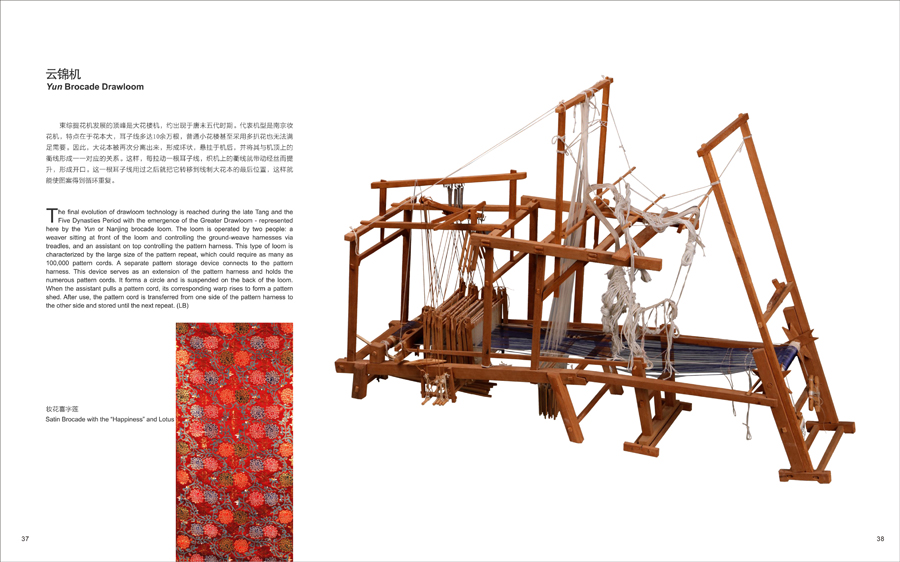

Yun Brocade Loom

The final evolution of drawloom technology is reached during the late Tang and the Five Dynasties Periods with the emergence of the Greater Drawloom—represented here by the Yun or Nanjing brocade loom. The loom is operated by two people: a weaver sitting at front of the loom and controlling the ground-weave harnesses via treadles, and an assistant on top controlling the pattern harness. This type of loom is characterized by the large size of the pattern repeat, which could require as many as 100,000 pattern cords. A separate pattern storage device connects to the pattern harness. This device serves as an extension of the pattern harness and holds the numerous pattern cords. It forms a circle and is suspended on the back of the loom. When the assistant pulls a pattern cord, its corresponding warp rises to form a pattern shed. After use, the pattern cord is transferred from one side of the pattern harness to the other side and stored until the next repeat. (Long Bo)

Brocaded Satin with Happiness and Lotus, Ming Dynasty (replica)

2. EASTERN ASIA: KOREA AND JAPAN

All Japan, Korea and east coast of China belong to one textile cultural circle. Back strap loom was used first, then the woji in China, izaribata loom in Japan and bettle in Korea, also called back strap treadle loom, on which natural shed was made by the thick sticker, and the other count shed by one shaft. It was a dominant type of loom during the Han to Tang Dynasties (1st - 9th centuries), however, more types of loom were also used afterwards, including the Jacquard loom was introduced into China. (Zhao Feng)

2.1 Backstrap Treadle Loom From Buyeo, Korea

This type of backstrap loom, called bettle, has a long history in Korea. To this day, it is still used for weaving a tabby fabric in silk, hemp, cotton, and ramie. Occasionally, it is also used to make ribbed gauze fabrics. For weaving a ribbed gauze, the loom would have two heddle rods. (Sim Yeunok)

3. MAINLAND SOUTHEAST ASIA

Mainland Southeast Asia, also known historically as Indochina, comprises Vietnam, Laos, Cambodia, Thailand, Myanmar, and West Malaysia. Nearly all weaving is done by women, who pass on the traditions of weaving to their daughters, from the sumptuous ikats of the Cambodian royal court of the 19th century, to the fantastical animal motifs of northern Laos, to the fine brocade robes of Vietnamese mandarins. It is evidenced that the oldest form of loom found widely in Southeast Asia was the backstrap loom, probably introduced in during the third millennium BCE. The influence of Chinese and Indian cultures was associated with the changes in textile technology. (Irene Lu)

Lao Loom with Vertical Pattern Heddles

From the market at Vientiane around 1993 Gift of Mary Connors

The Lao Tai groups use variations of a frame floor loom to produce elaborate textiles of tapestry, twill and plain weaves. Their cloth may be embellished with supplementary warp threads, as well as continuous and discontinuous supplementary weft threads. They have a two-heddle system to create and store intricate designs that enable the pattern "code" to be used and reused. The pattern is stored in the vertical heddle with bamboo or string pattern rods. This technology allows the weaver to preserve her creative expression realized in her laboriously picked design. The stored pattern is an important part of her heritage and can accompany her when she marries or travels; the original mobile app. (Carol Cassidy)

Coffin Screen

Tai Daeng People, Sam Neua Province, Laos Gift of Mary Connors

Thailand Weft Ikat Loom

From: Phu Phan, Sakon Nakhon Province, Thailand

Ikat weaving is famous in Thailand. This is a weft ikat loom from Thailand. To make a weft ikat, the weft threads are first wound around a frame called lak mii, whose width reflects the desired width of the final textile. Sections of the weft are then wrapped with continuous yarn, which acts as a resist in the dyeing process. These sections, called lam, correspond to the pattern steps in the final design. Varying the number of yarns per lam creates different visual effects. (Irene Lu)

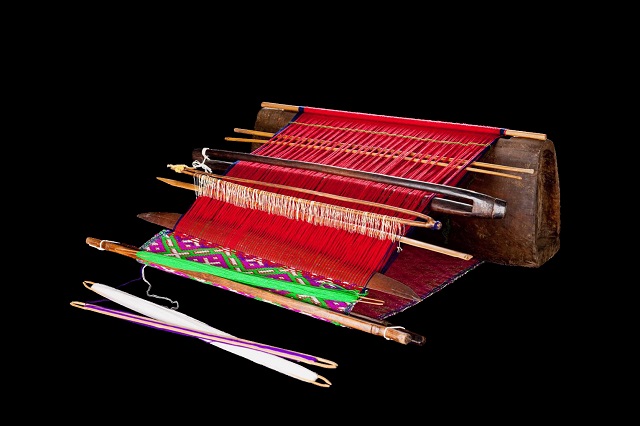

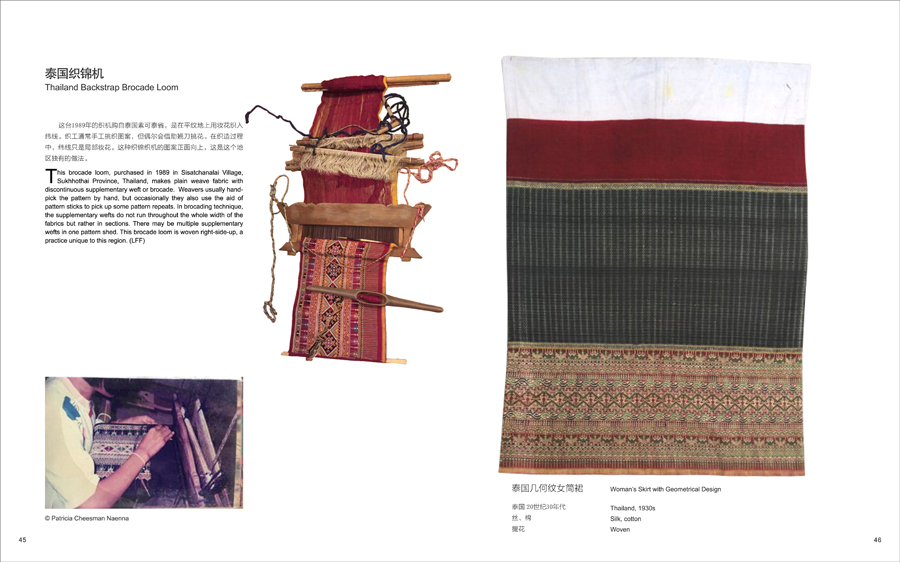

Thailand Backstrap Brocade Loom

Tai Phuan people Sisatchanalai Village, Sukhhothai Province, Thailand, 1989

This brocade loom makes plain weave fabric with discontinuous supplementary weft or brocade. Weavers usually hand-pick the pattern by hand, but occasionally they also use the aid of pattern sticks to pick up some pattern repeats. In brocading technique, the supplementary wefts do not run throughout the whole width of the fabrics but rather in sections. There may be multiple supplementary wefts in one pattern shed. This brocade loom is woven right-side-up, a practice unique to this region. (Irene Lu)

© Patricia Cheesman Naenna

Woman’s Skirt with Geometrical Design, Thailand, 1930s

Silk, cotton, Woven

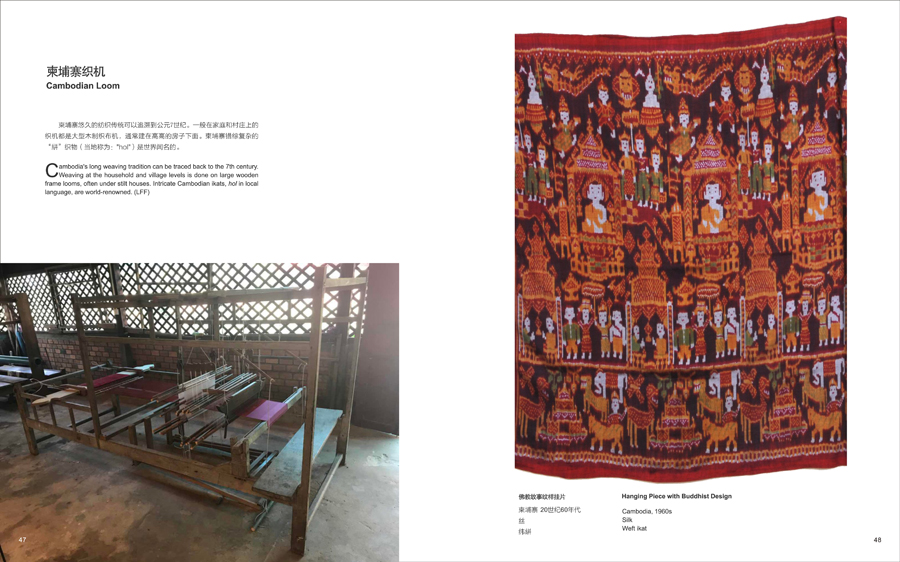

Cambodia loom

Cambodia's long weaving tradition can be traced back to the 7th century. Weaving at the household and village levels is done on large wooden frame looms, often under stilt houses. Intricate Cambodian ikats (hol) are world-renowned. (Irene Lu)

Hanging Piece with Buddhist Design

Cambodia, 1960s, Silk, Weft ikat